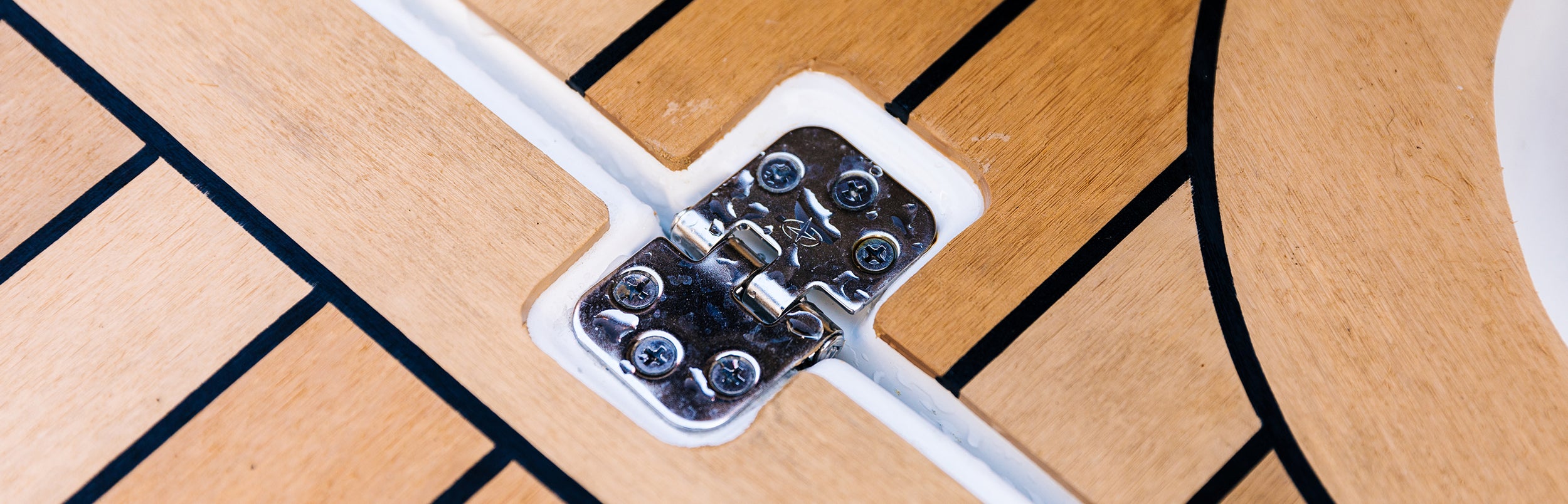

Stainless Steel Marine Boat Hinges

Your One-Stop Shop For Boat Hinges

No one knows boat hinges better than Gemlux. With decades of experience and product development, our marine hinge offerings include over 5,000 different shapes, styles, and barrel configurations.

The Gemlux Advantage is that we electropolish all hinges with our proprietary solution that consistently achieves a bright, uniform finish. This mirror-like coating protects the steel against corrosion in any environment. No matter where you need hinges – deck hatches, livewell, console doors, transom doors, side entry doors, and more – you can be assured that our top-quality hinges will stand the test of time.

Fasteners are NOT included. However, we offer a separate Installation Kit that includes chrome-plated SS fasteners.

- Regular price

- $37.73

- Sale price

-

$37.73$0.00 - Unit price

- per

- Regular price

- $9.68

- Sale price

-

$9.68$0.00 - Unit price

- per

- Regular price

- $37.23

- Sale price

-

$37.23$0.00 - Unit price

- per

- Regular price

- $33.81

- Sale price

-

$33.81$0.00 - Unit price

- per

- Regular price

- $31.14

- Sale price

-

$31.14$0.00 - Unit price

- per

- Page 1 of 6

- Next page